Tuck top boxes differ from other types of boxes like snap lock or auto bottom boxes in terms of their construction, closure mechanism, and suitability for different products. Here's a brief comparison:

Tuck top boxes:

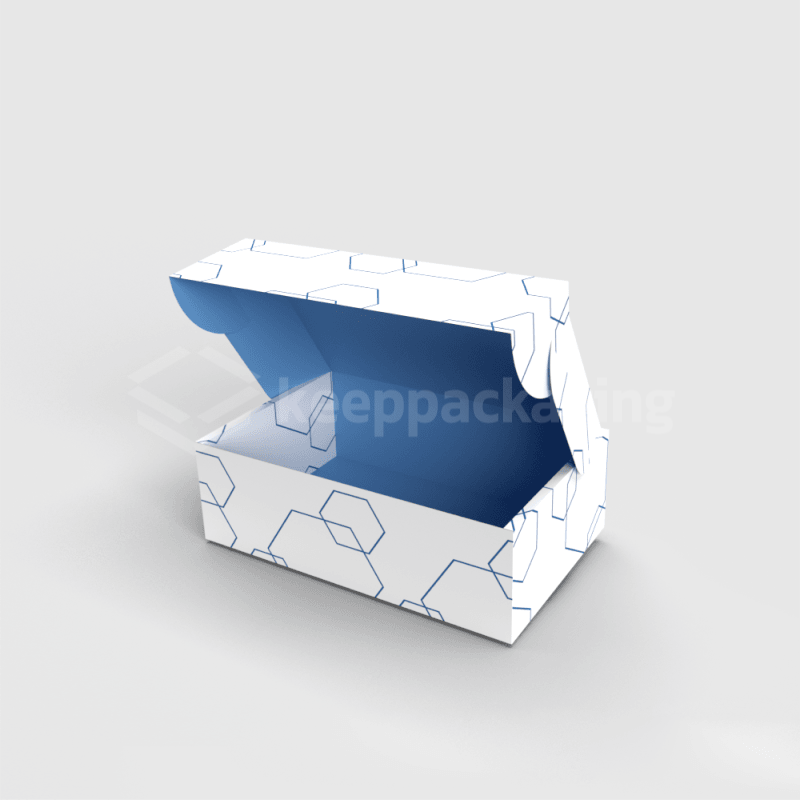

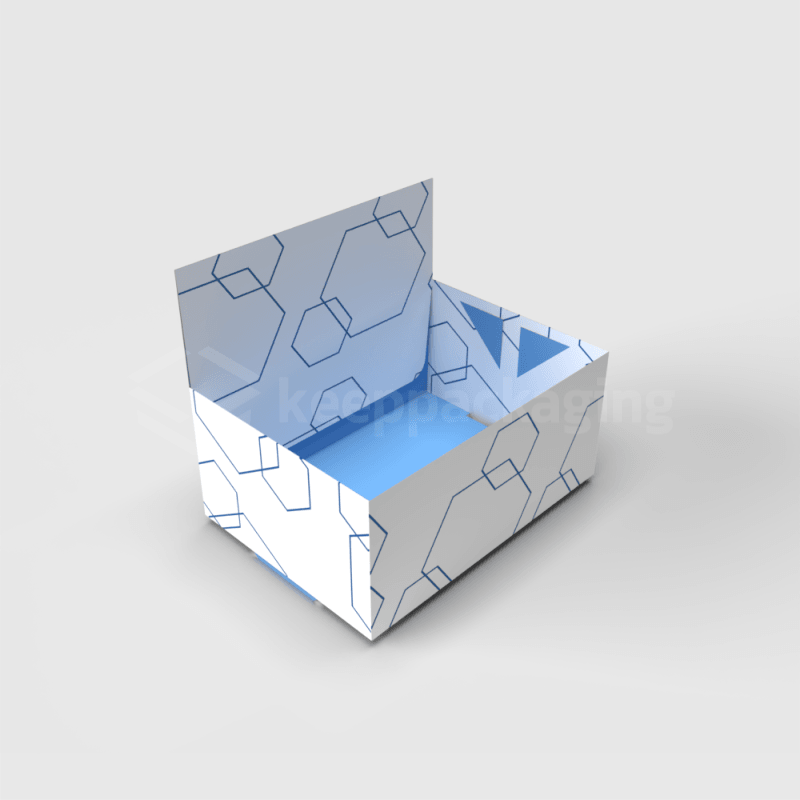

- Closure mechanism: Tuck top boxes have flaps on the top and bottom that tuck into the box to secure the contents. There are two main types: Reverse Tuck End (RTE) and Straight Tuck End (STE). In RTE boxes, the top and bottom flaps tuck in from opposite directions, while in STE boxes, both flaps tuck in from the same direction.

- Construction: These boxes are typically made from paperboard or cardboard and are easy to assemble.

- Suitability: Tuck top boxes are versatile and can be used for a wide range of products, including cosmetics, food items, and small electronics.

Snap lock boxes (also known as 1-2-3 bottom boxes):

- Closure mechanism: Snap lock boxes have a bottom closure that consists of three flaps that interlock to form a secure base. The top closure is usually a tuck top or another type of closure.

- Construction: These boxes are made from paperboard or cardboard and require manual assembly, but they provide a more robust base compared to tuck top boxes.

- Suitability: Snap lock boxes are suitable for heavier or bulkier products that require additional support at the base, such as glassware or larger food items.

Auto bottom boxes:

- Closure mechanism: Auto bottom boxes have a pre-glued bottom that automatically locks into place when the box is opened and expanded. The top closure can be a tuck top or another type of closure.

- Construction: These boxes are made from paperboard or cardboard and are designed for easy assembly, as the bottom locks into place without manual intervention.

- Suitability: Auto bottom boxes are ideal for heavier objects or products that require a strong base, as they offer the most robust support among the three types of boxes mentioned here.

When choosing the right type of box for your product, consider factors such as the weight and dimensions of the product, the desired presentation, and the ease of assembly. Each box type has its advantages and is suitable for different applications, so it's essential to select the one that best aligns with your marketing strategy and product requirements.